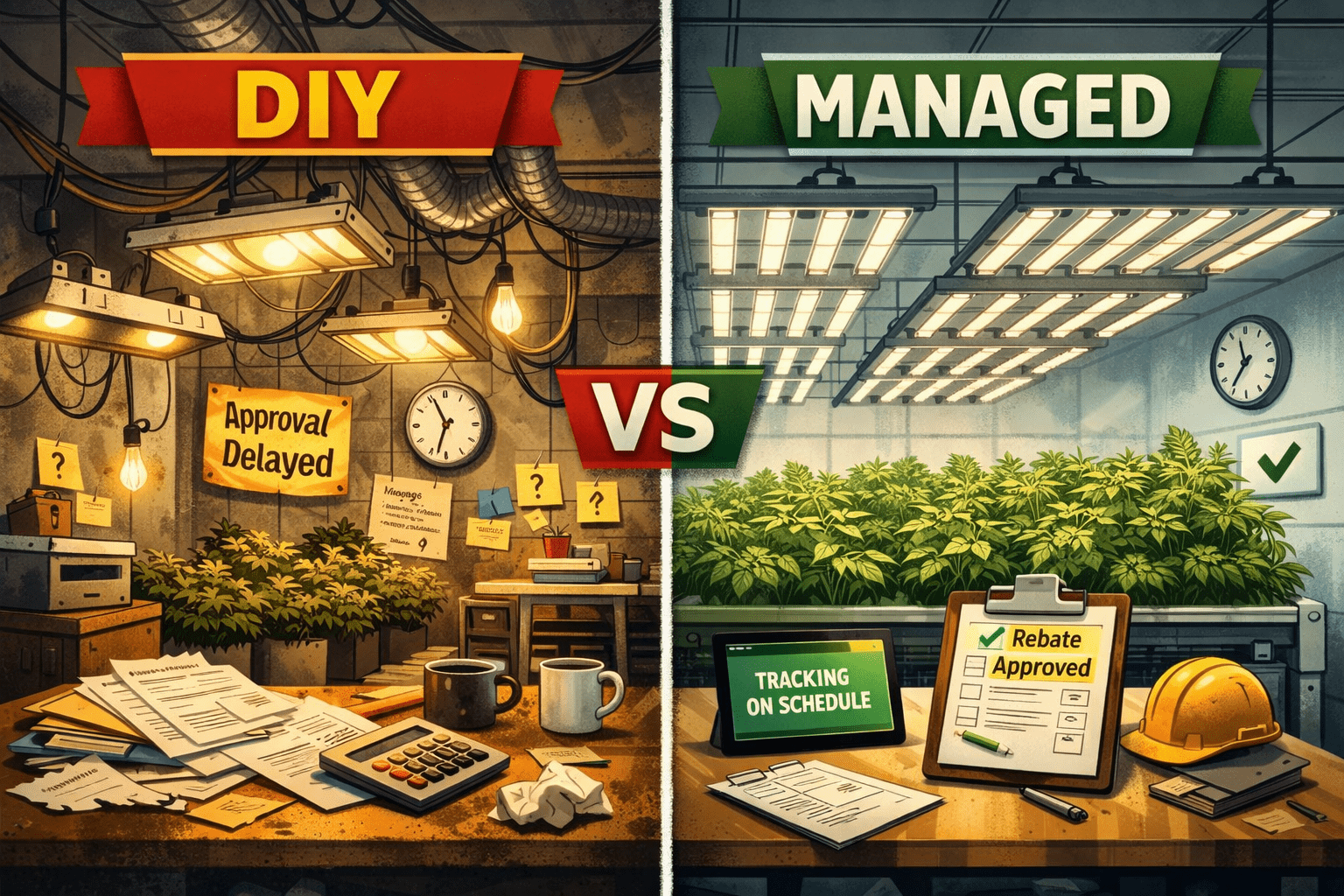

Proven outcomes across commercial cultivation projects show a clear divide between facilities that attempt rebates internally and those that rely on managed grow light rebates. The difference is rarely about effort or intelligence—it comes down to scope control, documentation discipline, and who actually owns the rebate timeline.

This comparison explains why many facilities start with a DIY approach, then switch to managed grow light rebates mid-project. If you want clarity before delays start, you can begin with a structured review here: request a rebate review.

1) Timeline Control vs Timeline Guessing

In DIY scenarios, timeline ownership is often unclear. Operations teams assume finance is tracking rebates, while finance assumes vendors or utilities will follow up automatically. In practice, this gap creates silent delays where applications sit untouched.

Based on managed grow light rebates, timeline ownership is explicit. Someone monitors submission dates, review windows, follow-up thresholds, and escalation paths. This reduces idle time and prevents applications from being deprioritized inside utility queues.

DIY rebate projects often assume that once paperwork is submitted, the process will move forward automatically. In reality, utility programs manage thousands of applications simultaneously, and projects without active follow-up tend to stall.

With managed grow light rebates, someone owns the timeline—tracking submissions, responding to reviewer questions, and preventing applications from sitting untouched for weeks.

2) One Locked Scope vs Rolling Scope Changes

Scope drift is one of the most common causes of rebate delays. Internal teams frequently adjust fixture quantities, models, or wattage after submission—sometimes without realizing those changes trigger re-review.

Facilities using managed grow light rebates lock the fixture schedule early and treat it as a controlled document.

Most scope issues begin at the product-selection stage. A clear reference point—such as commercial LED grow lights used in real projects (commercial lighting incentive program) —helps teams finalize specifications before rebate submission.

3) Baseline Defense vs Baseline Assumptions

Baseline challenges often appear weeks after submission, when reviewers request clarification on existing equipment. At that point, facilities scramble to reconstruct historical fixture data, runtime assumptions, or room configurations.

Facilities using managed grow light rebates document baseline conditions upfront. Existing fixture types, wattage ranges, and operating schedules are captured before installation begins, reducing the risk of incentive reductions later in the process.

Utilities do not approve equipment—they approve energy savings. DIY submissions often rely on assumed baselines that are difficult to defend under review.

With managed grow light rebates, baseline documentation is prepared in advance, including existing fixture type, input wattage, quantity, and runtime assumptions. This reduces pushback and prevents incentive reductions.

4) Inspection Readiness vs Inspection Surprises

Inspections are where many DIY rebate projects slow down. Missing serial numbers, unclear room assignments, or inconsistent photos frequently result in follow-up requests.

Managed grow light rebates treat inspection readiness as part of the original project scope—not an afterthought.

Inspection delays are especially common in multi-tier rooms or mobile layouts. Facilities using infrastructure such as V-track rolling bench systems typically require clearer room-level documentation to pass inspection without rework.

What Happens After Submission (And Why Projects Stall)

Many facilities assume the rebate process is linear: submit paperwork, wait, get paid. In reality, post-submission is where most friction occurs. Reviewers may pause applications due to incomplete data, internal backlog, or competing priorities.

With managed grow light rebates, post-submission activity is actively managed. Reviewer questions are answered quickly, documentation is revalidated when needed, and projects are kept visible within the review system.

5) Predictable Outcomes vs Uncertain Payouts

DIY rebates often succeed eventually—but timelines stretch, incentive amounts change, and internal resources get pulled into follow-up work.

Managed grow light rebates prioritize predictability: fewer surprises, cleaner approvals, and a clearer expectation of when incentives will be paid.

Why Facilities Switch to Managed Rebates Mid-Project

Most facilities do not plan to outsource rebates. They switch after encountering:

- Unexpected re-review requests

- Conflicting feedback from implementers

- Inspection issues that halt approval

- Timeline pressure from construction or harvest cycles

At that point, the question becomes less about cost and more about protecting the project.

Next Step: Decide Before the Process Decides for You

The cost of a delayed or reduced rebate often exceeds the cost of managing it correctly from the start. If you want clarity before committing resources, the fastest move is a structured rebate review.

Risk, ROI, and Why Facilities Stop Handling Rebates Internally

From a purely financial perspective, the largest rebate risk is not rejection—it is delay. Delayed incentives extend project payback periods and tie up capital longer than expected.

Facilities that switch to managed grow light rebates often do so after calculating internal time costs, opportunity cost, and the risk of reduced incentives. When rebates represent a meaningful portion of project ROI, managing them becomes a financial decision—not an administrative one.

FAQ: Managed Grow Light Rebates

Can we start DIY and switch to managed rebates later?

Yes, but switching later often means recovering stalled timelines or correcting documentation gaps. Early management typically delivers better outcomes.

Do managed rebates cost more than DIY?

In most cases, the cost of energy rebates for lighting upgrades is offset by faster approvals, fewer revisions, and more predictable incentive payouts.

Are managed rebates only for large facilities?

No. They are most valuable for projects with multiple rooms, tiers, or lighting categories—regardless of facility size.