Proven outcomes across commercial cultivation projects show that most problems related to the rebate inspection process do not start with equipment selection or incentive calculations. They surface when utilities verify whether the project described on paper actually exists in the facility as installed.

For many growers, inspection is treated as a formality. In reality, it is the point where incentives are either protected or quietly delayed, reduced, or placed back into review. This article explains the most common inspection triggers that stall rebates—and why inspection is often the stage where facilities stop handling rebates internally.

If inspection questions are already coming up, the fastest way to reduce risk is a structured review: request an inspection review.

What Rebate Inspections Actually Decide

Rebate inspections are not audits of cultivation practices and they are not meant to evaluate plant health, yield, or operational quality. Inspectors are there to confirm one thing:

Does the installed project match the approved rebate scope?

The rebate inspection process exists to verify that energy savings were not overstated and that the equipment, layout, and operation align with what was submitted for approval. When discrepancies appear, inspectors are required to flag them—even if the differences seem minor.

In practice, inspections focus on three verification dimensions:

- Equipment identity: model numbers, wattage, quantities

- Installation context: rooms, tiers, layouts, and placement

- Operational consistency: controls, settings, and intended runtime

Inspection problems arise when one or more of these elements was never clearly defined, documented, or controlled during the project.

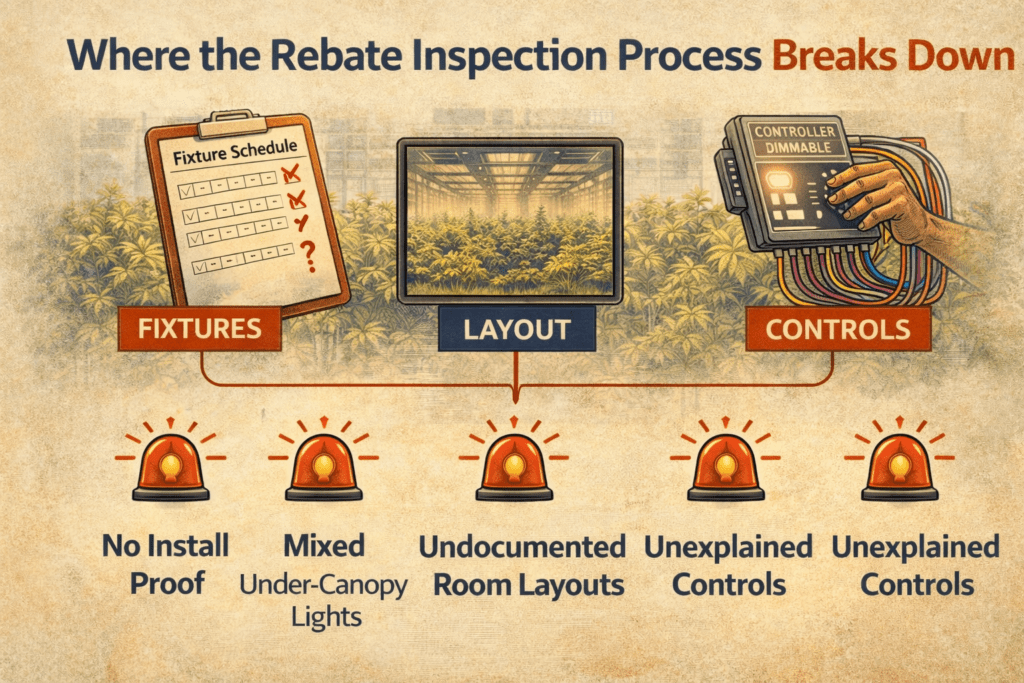

Where the Rebate Inspection Process Breaks Down

Most inspection delays come from predictable patterns. These are not rare edge cases—they are the same issues that appear repeatedly across commercial grow facilities.

Mismatch between approved scope and installed equipment

The most common inspection trigger is a mismatch between the approved fixture schedule and what inspectors see on site. This includes swapped models, adjusted wattage settings, quantity changes by room, or installing fixtures in locations not reflected in the original submission.

Missing or inconsistent install proof

Inspection proof is often collected after installation, which creates gaps. Inspectors may request wide-angle room photos, close-ups of fixture nameplates, or serial numbers that are no longer easily accessible. Each missing element introduces delay.

Layout and tiering that was never documented

Multi-tier rooms add complexity. Inspectors must understand how many fixtures exist per tier and how rooms are structured. Without even basic layout notes, reviewers cannot confidently verify savings assumptions.

Facilities using mobile infrastructure—such as V-track rolling bench systems —benefit from simple room-level documentation that explains layout during inspection.

Controls that exist but are not explained

Saying that fixtures are “dimmable” is not the same as documenting how controls are enforced. Inspectors often ask how dimming, scheduling, or room-level control is applied in practice. Vague answers frequently extend the rebate inspection process.

Why Inspection Is Where DIY Rebates Fail

Many facilities begin rebate projects internally because early steps feel manageable. Inspection changes that equation. Once reviewers begin asking detailed questions, the rebate process shifts from paperwork submission to risk management.

DIY rebate handling often breaks down during inspection for three reasons:

- No single owner of inspection documentation

- Scope changes that were never reconciled on paper

- Reactive responses instead of pre-built inspection packets

At this stage, delays are no longer administrative—they affect cash flow, project payback timelines, and internal credibility.

Facilities that use managed rebate approaches treat inspection as a planned phase, not a surprise. This typically includes:

- Locked fixture schedules

- Room-labeled photo libraries

- Controlled baseline documentation

- Direct communication with reviewers

The difference is not technical skill—it is ownership. Someone is responsible for ensuring the approved story matches the installed reality.

The rebate inspection process is not inherently risky. It becomes risky when it is treated as an afterthought.

Book a Minute Demo

If inspection questions are already appearing, the most effective next step is to review the project before delays compound.

Request an Inspection Review • About Our Team • Rebate Updates